Upload your sheet metal drawings and get a quote

Send us an online request for your sheet metal parts and get a feedback within 24 to 48 hours ! We quote for customers all over the world all kind of quantities. Just fill-in below sheet metal part quote request, send us your drawings and wait for your quote.

One step away from getting your quote

Detailed information about your need accelerate the quotation process !

You are in good hands, Elza, AGCIS operation manager is taking charge of your request.

How to work with AGCIS ?

What a sheet metal part quote looks like ?

After reviewing your sheet metal quote request we will come back to you with a quote including below items :

- Participation to tooling pricing* if any

- Part pricing for each quantity that you required

- Confirmation of specifications quoted if any difference from your request / drawings

- Detail about the shipment FOB (at China port) / DAP (delivery to your place tax non included) / DDP (delivery to your place tax included)

- Currency : We can quote in EUR / USD / CNY

- Lead time for the tooling and first samples, lead time for serial production and delivery

*: Tooling costs are a one time investment

What is the cost of manufacturing sheet metal parts ?

In order to get the best pricing for your sheet metal parts project it is important to understand how the pricing is made and which are the cost impacting contraints.

Non recurring tooling costs

According to the complexity of your part and the quantity needed some tooling costs may need to be applied. Tooling are often use to reduce the number of manufacturing steps and to save cost for high quantities orders.

Parts costs

There are different technology solutions available for the manufacturing of sheet metal parts. As sheet metal specialist, AGCIS will choose the most adapt on for better price/quality ratio of your parts.

- Punching is usually the cheapest and quickest way of making holes, but the cut may include burrs and some tooling costs may be needed

- Laser cutting or water pressure cutting are very effective and provide good cut quality but are slower to process.

- Unless included in a big punching tool, each bend on a part has to be done one at a time.

- Inserts maybe punched, welded or screwed on the parts, the number of insert will have an important impact on the part price. There are also different quality of inserts, local Chinese inserts been less expensive than international brand, don’t hesitate to specify if you need specific brand.

- Materials : there are many available materials for metal sheet parts, below is their listing in decreasing value : Copper > stainless steel > Aluminum > brass > Cold Rolled steel (CRS) > Zinc plated steel > Aluzinc

- Thickness of the parts : the thicker the part the more expensive it will be to proceed.

- Surface treatment : Painting, anodisation, alodine coating, galvanization, tin coating costs need to be assessed case by case on the specification.

- Packaging : metal sheet parts are often easy to be deformed if not well packed, to be considered from the start of the project.

How long does it take to manufacture sheet metal parts ?

The normal lead time for manufacturing is 1 month, it can be a little longer if complex tooling have to be made.

Times of shipment of the parts is not included, for air shipment you have to add 3 to 5 days and for see shipment 1,5 month to Europe or US.

FAQ

Which metal do we offer ?

Most of the metal available on the market are possible : Stainless steel, carbon steel / CRS, Aluminium, Copper, Brass, Zinc coated steel, Aluzinc etc..

What are the tolerances that can be respected in sheet metal manufacturing ?

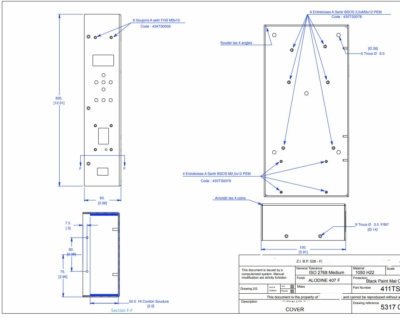

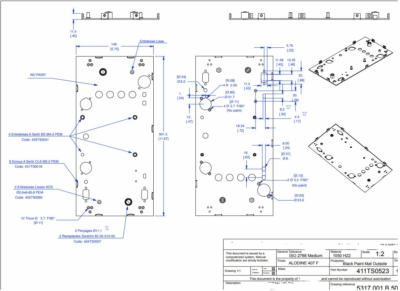

AGCIS is usually using tolerances from ISO2768 norm, which includes different levels of tolerancing, all the levels can be achieved, but the stricter the tolerance the higher the price.

What are AGCIS references on sheet metal parts ?

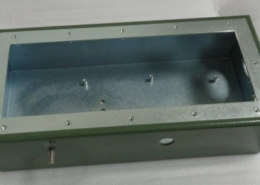

AGCIS have been sheet metal parts since year 2000, we worked on many different projects including electronic module casings, cabinets, supports, camera casing and so on.. Don’t hesitate to browse our sheet metal portfolio for a thoughtful overview of our past realizations.

Which quantities are ok for sheet metal manufacturing ?

We provide solutions from prototype to ten thousands or parts per reference.

How to pay my order ?

Usual payment terms for new project are is 50% at the order and remaining 50% after sample validation. Series order are often invoiced 30% at the order and remaining at the expedition.

We accept below payments :

- T/T bank transfer to our account in Belgium (€), US ($) or China (CNY)

- L/C payments are also possible

- Payment to our PayPal account, with a 5% mark-up. It is possible to pay our PayPal invoices with credit card.

Each project is unique

Don’t hesitate to contact us for discussing your project, we are here to help you get the cheapest manufacturing solution for your sheet metal part.

Add your drawings for quicker feedback.

Cooperation process

Concerned about the confidentiality of your documents ?

At AGCIS, safeguarding the information provided by our contacts and customers is a top priority. That’s why we strictly adhere to the enclosed NDA by default, even if no formal agreement is signed between you and AGCIS.

![[:en]Front face metal sheet [:fr]face avant tôlerie [:en]painted metal sheet [:fr]tôlerie acier peint](https://agcis.com/wp-content/uploads/2017/11/P1140498-241x179.webp)

![[:en]Metal sheet processing [:fr]Tôlerie [:en]Processing of metal sheets in China [:fr]Tôlerie en Chine](https://agcis.com/wp-content/uploads/2017/11/FMS-241x179.webp)

![[:en]Aluminium casing [:fr]boitier électronique aluminium [:en]casing manufacturing [:fr]fabrication de boitier électronique](https://agcis.com/wp-content/uploads/2017/11/P1010879-241x179.webp)

![[:en]Camera casing [:fr]Boitier caméra [:en]Casing from China [:fr]Boitiers fabriqués en Chine](https://agcis.com/wp-content/uploads/2014/09/P1130462-241x179.webp)

![[:en]bending press [:fr]presse tôlerie [:en]bending press in China [:fr]presse tôlerie en Chine](https://agcis.com/wp-content/uploads/2017/11/bending-press-400x225.webp)