PART DESCRIPTION :

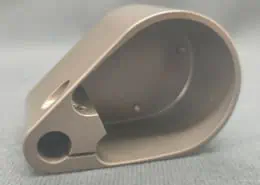

Watch Case Body:

Precision stainless-steel case body designed for premium wristwatches.

Provides the main structural housing for the movement, crystal, and case back.

Made by machining, ensuring high accuracy, refined surfaces, and stable geometry.

Case Back:

Circular stainless-steel back cover crafted for secure protection of the watch movement.

Ensures tight rear closure and long-term mechanical stability.

Made by machining and polishing, delivering corrosion resistance and precise fitment.

Retaining Ring:

Inner stainless-steel ring that positions and secures the watch movement inside the case.

Maintains correct alignment between the crystal, bezel, and internal watch components.

Made by machining, guaranteeing tight tolerances and reliable assembly.

DIMENSIONS :

Watch Case Body:

Dimensions: 45.00 mm wide, 45.00 mm long, and 14.50 mm high, with a 33.20 mm inner opening for movement fitting.

Features precision-machined steps and mounting points for watch assembly.

Case Back:

Dimensions: 33.60 mm in diameter and 1.77 mm thick, with a 26.40 mm inner step diameter for secure rear closure.

Flat polished surface designed for accurate sealing and assembly.

Retaining Ring:

Dimensions: 38.00 mm in diameter and 1.10 mm thick, with a 30.00 mm inner diameter and functional step at 33.60 mm.

Machined grooves and slots ensure tight fitment inside the watch case.

USAGE :

Suitable for high-end wristwatch assemblies requiring precise structural alignment between the glass, bezel, movement, and case back.

Provides stable housing, consistent tolerance control, and reliable long-term performance for premium mechanical and quartz watches.