Browse our extrusion projects

AGC offers mainly aluminum extrusion parts but we may also offer different materials (rubber, plastic, steel). Our customers are particularly interested in our low cost solutions of tooling and extrusion parts finishing.

Extrusion process explained

Extrusion is realized by pushing material through a fix die within a high pressure press. The output will be extrusion bars with a cross-sectional profile, shaped almost as a negative of the die or dies for complex shapes.

Material is usually heated (around 400°C for aluminum) before entering the press in order to facilitate part shaping. Bars are usually extruded to 12m long, but longer or shorter ones may be available for specific usages. The parts extruded will have a constant cross-sectional shape all along its length. Heat treatment may be done after extrusion to remove stress from the profiles.

Profiles finishing

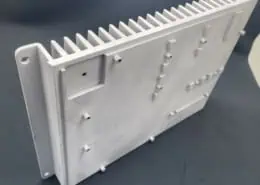

Next to the extrusion of the profiles, several additional operations can be conducted:

– Cutting along the lenght of width of the profiles.

– Drilling /thread drilling of holes along the profiles

– Machining for complementary shapes that cannot be done by extrusion only.

– Deburring

– Surface treatment (mostly anodisation for aluminum)

Our extrusion solution, limits & possibilities

– For the aluminum our minimum of order is between 50 and 500kg of extrusion parts according to part cross section size. This is corresponding to the break-even point for the setting up of die on our presses.

– Parts made from extrusion can be from several grams to several kilos (please refer to portfolios to scroll some of our realisations)

– We can acheive very good precision, up to +/- 0,02mm and also a good dimensional stability over the time.

– Surface aspect of the parts are smooth with a « brushed » effect that can be stressed more or less.

![[:en]low cost heatsink [:fr]radiateur alu pas cher](https://agcis.com/wp-content/uploads/2014/09/P1150168-241x179.webp)

![[:en]Extrusion solution China [:fr]Solution d'extrusion en Chine](https://agcis.com/wp-content/uploads/2014/09/P1150177-241x179.webp)