Lost wax casting, also known as water glass investment casting or ‘cire perdue’ (French), is a process that involves pouring metal alloys into a wax mold to create a pattern. Silver, gold, brass, and bronze are the most common metals used in this process. It is one of the oldest metal-forming techniques, dating back 6000 years, and is still commonly used for making jewelry, dental implants, and sculptures. Investment casting, in its industrial form, is a popular way to make precision metal parts and prototypes in engineering and manufacturing. Lost wax casting provides precision parts in the order of a tenth of a millimeter.

Advantages of Lost Wax Casting

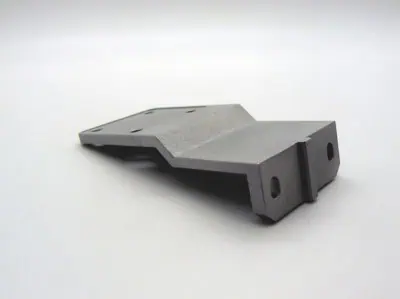

- Lost Wax Casting can manufacture and render thin-wall, complex shapes, near net-shapes, delicate floral forms, difficult-to-machine materials, multi-working procedures parts, and multiple components into one piece.

- Any material can be used in investment casting, and production capability is quite versatile. Aluminum, titanium alloys, magnesium alloys, copper alloys, cobalt, steels of all kinds, nickel-based heat-resistant alloys, and hard materials are all acceptable casting materials.

- In comparison to other casting methods, investment casting can achieve the goal of a short working time and low cost by avoiding the need for numerous working procedures, large mechanical processes, and low productivity and material waste to produce high-cost components.

- Material waste and mass production can be reduced by lost wax casting.

- Only lost wax casting allows for the production of a wide range of products across various industries. An example of a larger-scale product that can be manufactured using investment casting is turbine blades with complex shapes for the power generation industry. Another example is the firearm industry, where investment casting is used for smaller precision parts such as firearm triggers, receivers, and hammers.

The Process

- An original model is made from wax, clay, or other material.

- This model is then cast and polished to produce a master pattern.

- The mold is filled with molten wax through injection or pouring.

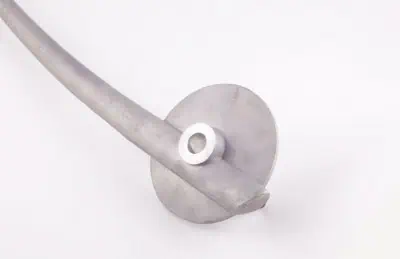

- Sprues are added to the wax and joined to create a tree-like structure that allows molten metal to fill the cavity later.

- Then it is dipped in a silica slurry or placed in a flask of liquid investment plaster.

- The flask is put upside down in a kiln after the investment material has dried, melting the wax and leaving a negative cavity in the form of the original model.

- Melted metal is then poured into the cavity, with the metal being drawn in by gravity or vacuum pressure.

- The investment mold is quenched in water to remove the refractory plaster after the molten metal has cooled somewhat.

Lost Wax Foundry

The lost wax casting subcontracting from China uses carbon steel, stainless steel, aluminum, and nonferrous metals. Finition on 3-4 axis machining centers or surface treatment additional protection may be included in the services. For the production of relatively simple parts of metals, sand casting foundries are also functional, they offer cheaper parts, by worst surface quality and less precise dimension tolerances. The shell foundry helps to optimize the production of small and medium-series precision parts.

Customers can manufacture parts in China to save money while maintaining a high level of quality. China has been mastering the casting process since the Song dynasty, there is a very strong local experience and highly competitive operational costs in mold and parts manufacturing.