Looking for a pricing of your plastic parts ?

Send us an online request for your plastic molding project and get a feedback within 24 to 48 hours ! We quote for customers all over the world all kind of quantities. Just fill-in below online plastic molding quote request, send us your drawings and wait for your quote.

One step away from getting your quote

Detailed information about your need accelerate the quotation process !

You are in good hands, Elza, AGCIS operation manager is taking charge of your request.

How to work with AGCIS ?

What a plastic injection quote looks like ?

After reviewing your plastic molding quote request we will come back to you with a quote including below items :

- Participation to tooling pricing*

- Part pricing for each quantity that you required

- Confirmation of specifications quoted if any difference from your request / drawings

- Detail about the shipment FOB (at China port) / DAP (delivery to your place tax non included) / DDP (delivery to your place tax included)

- Currency : We can quote in EUR / USD / CNY

- Lead time for the tooling and first injection, lead time for serial production and delivery

*: Tooling costs are a one time investment for the setting up of the mold(s)

What is the cost of plastic injection ?

In order to get the best pricing for your plastic injection it is important to understand how the pricing is made and which are the cost impacting contraints.

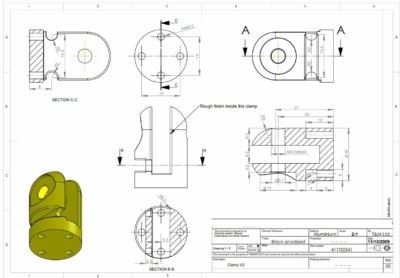

Injection molds costs

In plastic injection molding, manufacturing of the molds is a very important cost. The good news is that it is a one time investment.

Plastic injection molds costs something between several thousands USD to several tenth of thousands USD depending on below factors :

- Size of the part to inject : it will impact the size of the mold.

- Number of cavities : increase the mold costs but lower the price cost.

- Life expectancy of the tooling : number of shots : the higher the number of shots the more expensive the molding steel.

- Complexity of the parts : for complex parts slides and venting needs to be added which cost extra

- Aspect of the part : high quality polished surface will need extra processing costs and maybe specific inserts (for optical plastic parts for example)

Parts costs

Plastic injected parts are usually very cheap and their quality is quite stable, but some factors impact their price and need to be considered in the design stage :

- Batch quantities : molds needs to be set up on injection press for each production this operation takes time and cost money, so the more parts done in one batch the lower the unit price

- Number of cavities, as mentioned above the more the cavities the lower the unit price

- Size and complexity of the parts, complex parts will need bigger press with more expensive processing and longer injection time.

- Materials : choice of plastic material is important as different injectable plastics have different cost.

- Deburing : plastic flash are usually present on the edges of the parts after un-molding, deburing can be done manually of with deburing tools.

- Packaging : on top of the obvious packaging costs, as plastic parts are cheap the impact of transportation costs can be very significant if they are not optimized to imbricated.

How long does it take to mold plastic parts ?

For the first order the tooling must be manufactured and tested. Lead time from the start of the project and first trial injection is usually 1 month.

Once the tooling has been validated series injection will be done in a 3/4 weeks time frame.

Times of shipment of the parts is not included, for air shipment you have to add 3 to 5 days and for see shipment 1,5 month to Europe or US.

FAQ

Which plastics do we propose ?

Please refer to our article on the available injectable plastics, AGCIS have access to a wide range of material ressources, we can source materials or offer alternatives matching your needs.

What are AGCIS references on plastic injection ?

AGCIS have been providing plastic injected parts since year 2000, we worked on many different projects including UV resistant injections, UL certified projects, transparent optics and so on.. Don’t hesitate to browse our plastic injection portfolio for a thoughtful overview of our past realizations.

Which quantities are ok for plastic injection ?

There is obviously no upper limitation and we provide solutions for small quantities plastic injection, including silicon molds and aluminium molds. For less than 10 parts we strongly recommend to work with 3D printing for your plastic parts.

How to pay for the mold and the parts ?

Usual payment terms for setting a new mold is 50% at the order and remaining 50% after sample validation.

We accept below payments :

- T/T bank transfer to our account in Belgium (€), US ($) or China (CNY)

- L/C payments are also possible

- Payment to our PayPal account, with a 5% mark-up. It is possible to pay our PayPal invoices with credit card.

Add your drawings for quicker feedback.

Cooperation process

Concerned about the confidentiality of your documents ?

At AGCIS, safeguarding the information provided by our contacts and customers is a top priority. That’s why we strictly adhere to the enclosed NDA by default, even if no formal agreement is signed between you and AGCIS.

![[:en]Thread plastic injection [:fr]Injection plastique filetages [:en]Thread plastic from China [:fr] Filetage plastique Chine](https://agcis.com/wp-content/uploads/2014/09/P1150241-241x179.webp)

![[:en]Plastic lamp cover [:fr]Support lampe plastique [:en] supply injection from China [:fr]fourniture d'injection depuis la Chine](https://agcis.com/wp-content/uploads/2014/09/P1150409-241x179.webp)

![[:en]plastic dome [:fr]Dome plastique [:en] camera dome [:fr]dome caméra](https://agcis.com/wp-content/uploads/2014/09/P1130447-241x179.webp)

![[:en] Plastic front face [:fr]Face avant plastique [:en]injection front face [:fr]Injection de face avant](https://agcis.com/wp-content/uploads/2014/09/P1150367-241x179.webp)

![[:en]Plastic lens array [:fr] Matrice lentilles plastique [:en]Injection of optics in China [:fr]Injection optique en Chine](https://agcis.com/wp-content/uploads/2014/09/P1150397-241x179.webp)

![[:en]Plastic injection China [:fr]Injection plastique en Chine [:en]Plastic part in China [:fr]Pièce plastique en Chine](https://agcis.com/wp-content/uploads/2014/09/P1150392-241x179.webp)

![[:en]beacon plastic injection [:fr]Support signalisation plastique small quantity plastic injection](https://agcis.com/wp-content/uploads/2014/09/P1150393-241x179.webp)

![[:en]Plastic lamp Assembly [:fr]Assemblage lampe plastique [:en]Integration plastic and electronic [:fr]Intégration de plastique et d'électronique](https://agcis.com/wp-content/uploads/2014/09/P1150407-241x179.webp)