Upload your casting part drawings and get a quote

Send us an online request for your casting needs and get a feedback within 24 to 48 hours ! We quote for customers all over the world all kind of quantities. Just fill-in below online casting quote request, send us your drawings and wait for your quote.

One step away from getting your quote

Detailed information about your need accelerate the quotation process !

You are in good hands, Elza, AGCIS operation manager is taking charge of your request.

How to work with AGCIS ?

What a casting quote looks like ?

After reviewing your casting quote request we will come back to you with a quote including below items :

- Participation to tooling pricing* including number of cavities for die casting

- Part pricing for each quantity that you required

- Confirmation of the material quoted

- Confirmation of the coating if any

- Confirmation of specifications quoted if any difference from your request / drawings

- Detail about the shipment FOB (at China port) / DAP (delivery to your place tax non included) / DDP (delivery to your place tax included)

- Currency : We can quote in EUR / USD / CNY

- Lead time for the tooling and first samples, lead time for serial production and delivery

*: Tooling costs are a one time investment

What is the cost of casting metal parts ?

In order to get the best pricing for your casting project it is important to understand how the pricing is made and which are the cost impacting contraints.

Non-recurring tooling costs

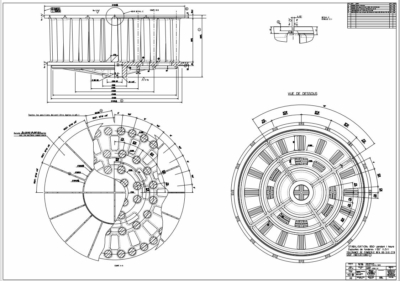

Development of specific tooling is mandatory for manufacturing metal parts by casting. No need to worry we are taking charge of the design of the tooling according to your parts drawings. Tooling coasts ranges from several tenth thousands of USD for complex die casting to mere hundreds of USD for simple sand or wax castings.

Tools will stay in China, so you don’t have to worry about storage and we usually don’t invoice maintenance of the molds.

Casting parts costs

Factors that are impacting the cost of casting.

- Technology to be used for casting :

- Die casting for high quantities, small wall thickness Alu / Magnesium / Zamak parts : low part price but expensive tooling

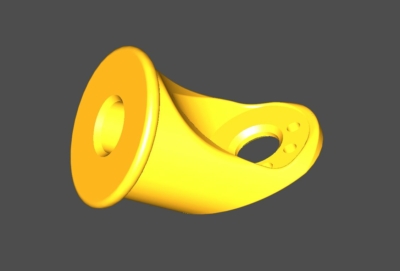

- Investment casting (or gravity casting) : moderate pricing, good part aspect and moderate mold cost

- Lost wax casting : low tooling cost, moderate part price, good aspect

- Sand casting : low tooling cost, moderate part price, possible for small quantities, non-smooth surface aspect.

- Complexity of the parts : more complex parts will need more complex tooling and longer manufacturing time.

- Additional machining : parts with specific surface quality that cannot be achieved by casting with need to be machine after casting.

- Deburring, according to the geometry of the part deburring may be a complex step, if can be done manually of with deburring tools for high quantities orders.

- Quantity, in casting the higher the quantity the lowest the price, batch quantities should be maximized.

- Surface treatment, typically anodisation would cost 0.02 to 0.1 USD per cm2, while painting painting would cost half of it (ball point estimation).

- Packaging : metal parts need to be well protected to avoid corrosion and dents.

How long does it take to manufacture casting parts ?

The normal lead time for tooling manufacturing including initial sample manufacturing is 1 to 2 month. Once the samples have been validated, series casting will also take approximately one month, more if extra machining should be done.

Times of shipment of the parts is not included, for air shipment you have to add 3 to 5 days and for see shipment 1,5 month to Europe or US.

FAQ

Which metal can be molded ?

Most of the metal can be molded, including stainless steel, aluminium, carbon steel, Zamak, and magnesium, but some limitation applies to the casting technology available for each material.

What are AGCIS references on casting parts ?

AGCIS have been providing cating parts since year 2000, we worked on many different projects including transport industry parts, industrial parts, structural parts and so on.. Don’t hesitate to browse our casting parts portfolio for a thoughtful overview of our past realizations.

Which quantities are ok for castings ?

It can start from several parts for big sand casting to tenth of thousands for high pressure die-casting.

How to pay my order ?

Usual payment terms for new project are is 50% at the order and remaining 50% after sample validation. Series order are often invoiced 30% at the order and remaining at the expedition.

We accept below payments :

- T/T bank transfer to our account in Belgium (€), US ($) or China (CNY)

- L/C payments are also possible

- Payment to our PayPal account, with a 5% mark-up. It is possible to pay our PayPal invoices with credit card.

Each project is unique

Don’t hesitate to contact us for discussing your project, we are here to help you get the cheapest manufacturing solution for your casting part.

Add your drawings for quicker feedback.

Cooperation process

Concerned about the confidentiality of your documents ?

At AGCIS, safeguarding the information provided by our contacts and customers is a top priority. That’s why we strictly adhere to the enclosed NDA by default, even if no formal agreement is signed between you and AGCIS.

![[:en] Die casting cover [:fr] support en aluminium sous-pression Die casting in China](https://agcis.com/wp-content/uploads/2015/06/Socle-GiroLed-1-241x179.webp)

![[:en]Die casting low cost [:fr]Injection sous-pression pas chère supplier die casting](https://agcis.com/wp-content/uploads/2014/09/P1150170-241x179.webp)