For the public the most visible part of the electronic components supply crisis is that the production lines of most of the big automotive companies went to a halt due to the shortage of microchips.

Origins of the electronic components shortage

Without the crisis created by the apparition of the COVID, production capacities of semi-conductors would certainly be tense, but not as tense as they currently are. COVID crisis, directly and indirectly created :

- lock-down policies that bring factories to temporary halting the production and therefore stopping production of electronic components for a while.

- lack of workers and blocked logistic hubs, delaying deliveries of goods and increasing the on-transit quantity of components not available on the market.

- increased the demand of new remote workers for computers and tablets, which in turn increased the demand of microchips for their manufacturing.

At this COVID crisis, major instigator of the shortage, the US restriction on Chinese exportations, shifted many orders for simple chips from China to big foundry (TSMC / Samsung) adding extra pressure on their already saturated production lines.

Microchips supply chain goes off tracks

As presented in the theory of Chaos, a butterfly flapping his wings in Brasil may created a hurricane in Texas.

In our case, the butterfly is rather imposing because it is the automotive industry, which, seeing its sales blocked by the restrictions linked to the pandemic, has drastically reduced its orders for electronic components.

However, following the various support policies for economic recovery, the return of orders took place at a steady pace, while the production capacities of component manufacturers were not able to follow.

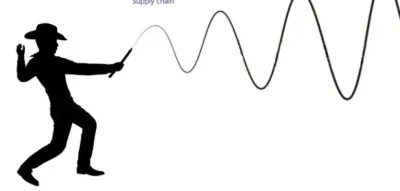

Of course, this grain of sand in the gears of the well-oiled supply chain of electronic components has created what is known as the “bullwhip effect” (reminiscent of a slight movement of a handle at the end of a whip which turns into a movement of great amplitude at its opposite):

- Over-anticipation of the impact of COVID: cancellation of orders, reduction in production, refocusing of production on other products.

- Resumption of orders, difficulties in obtaining supplies and therefore overestimation of own needs in order to increase security stocks.

- Increased shortage of components

- Increase in prices, creating a short-market and encouraging certain intermediaries to practice stockpiling to surf on scarcity and contribute to an even greater increase in selling prices.

Perspectives

An unbalanced market, just like a whip will eventually rebalance if there is no new wrist flick (uncertainty crisis), the war in Ukraine was of course another wrist flick and it is by nature difficult to predict them.

However, a lot of stock has been made by the decision makers, some projects due to the lack of available components simply had to be canceled, in addition many investment projects in new production capacities of electronic components have been carried out. As for demand, driven by the key sectors of automotive, video games and graphics cards, there is reason for huge increased needs over the long term, a return to equilibrium is therefore to be expected in 2024/2025.