Browse our precision machining projects

From the high speed machining center to the manual lathe, AGC uses of a comprehensive field of machining equipements to offer you the best pricing, fitting your needs of custom mecanical parts.

Working with us means : respect of materials, tolerances, constant surface treatment application, protective packaging of your parts and flexible delivery all over the world. In few words : simple and competitive one stop solution.

Testpunkt mit Feder

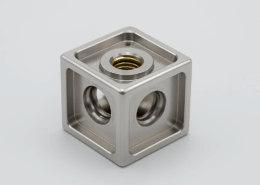

bearbeiteter Würfel

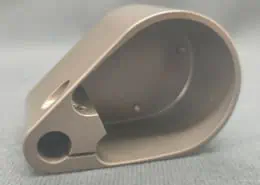

Projektorgehäuse

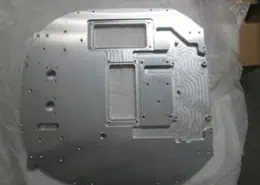

Aluminium eloxierter Kühlkörper

Stahlklinge

Edelstahl-Stift

Opto-mechanisches Alu-Gehäuse

Klinge aus rostfreiem Edelstahl

Precision machining technical expertise

- To get your custom machined parts, trust the experience of an expert :

- Support for selection of the best machining solution for your parts

- Tolerances validation before launching machining

- Quality control report provided by our quality technicians.

Machining solutions chart:

| Equipement | Detail | Remarks |

|---|---|---|

| Lathe | Parts in rotation, material removal with a cutting tool | Turning is mainly used for machining of cylindrical parts |

| Bar-turning | Automatic lathe fed directly by metal bars | Used for revolution parts of limited dimensions, medium to big series only |

| Cutting machine | Working with either tooling tool, wire, laser or water jet | The choice of the equipment is made according to the material and the cutting edge aspect required |

| Electro-erosion (EDM) | Material removal by electric discharge from an electrode in conductive liquid | Can produce complex shapes, high precision and good surface aspect, however is rather slow, mostly used for tooling manufacturing and small series |

| Sharpener | Machining of a cutting sharp edge on a flat part by grinding | For cutting blades finishing |

| Manufacturing center | Cutting tools in high rotational speed, remove matierial from a part | There are numerous types of machining centers, 3 axes, 4 axes, 5 axes, high speed, choosen according to the complexity of the requested part. |

Finishing and Surface treatments

– Different surface finishing are possible : sand blasting, tribofinishing, brushing, shotpeening, polishing, mirror polishing

– We also offer solutions for surface treatment of machined parts, following material, customer needs and reglementary requests (Rohs / Reach) : anodisation, zinc coating, chroming, painting, burnishing

Our quality guaranty

- – Control report for each delivery

- – Care given to possible quality issues of machining : dimensions within tolerances, surface finishing, chamfering, thread go/no go gauge control, deburring..

- – Raw material upstream checks, traceabillity