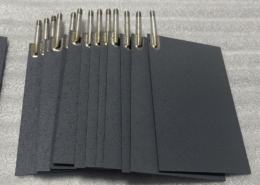

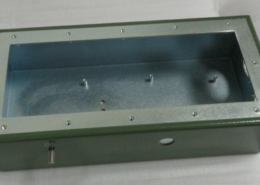

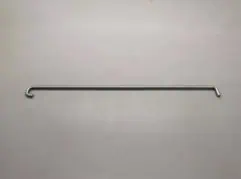

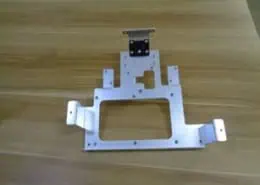

Browse our metal sheets projects

Metal sheets components are often used as support (electronics, lighting, equipments, machines) and are not part of our customers high value core competencies.

– Parts in all available materials : Stainless steel, aluminium, CRS, aluzinc, copper, plastic (Mylar, Formex)

– Diverse surface treatment solutions : painting, textured painting, zinc-coating, Alodine, Surtec, tin coating

– Report for each expedition from our quality control technicians

Metal sheet working operations chart:

| Action | Equipement | Détail |

|---|---|---|

| Bending | Bending press | Enables metal sheet bending with a define angle and internal radius |

| Punching | Punching press / NC punching press | Can do cutting, marking or perforation of the metal sheets. |

| Stamping | Stamping press | Shape a metal sheet by stamping a tooling with high pressure |

| Welding | Manual or welding robot | Permit assembly of different metal sheet parts and the adding of inserts or other components |

| Paint | Painting line | Cleaning, degreasing, painting and drying |

| Assembly | Manual, screwing devices, stamping | Assembly of different components to form a complex product |

| Cutting | Laser, water jet, punching or presse | The choice of the machine depend on the material, it’s thickness and the quality of the edge required after cutting |

Packing and Logistics

– In order to guaranty the best surface aspect we offer individual packages, compartmented cartons / boxes and the possibility to have a protection film on the critical cosmetic surfaces.

– Shipments are from China to worldwide destinations, mainly by maritime freight, starting from a minimum of 1 pallet

Our quality guaranty

– Quality control report for each shipment

– Specific care given to usual issues on metal sheet components: edge rust protection, surface aspect, thread testing, deburring

– Upstream check of raw material, tracability